This is a very interesting development. Besides the headline the article explains some of the traditional limitations and complications of PV solar manufacturing today with extreme temperatures and vacuum conditions, performed in specific batches.

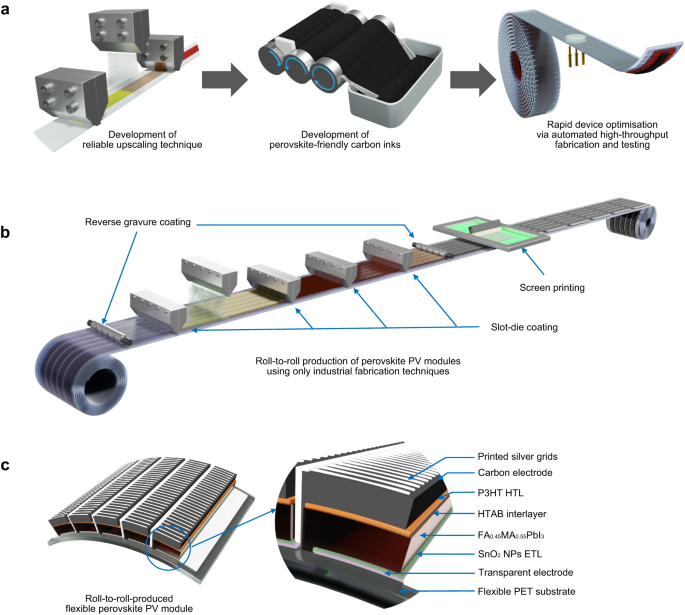

This new technology seems to do for PV solar what Henry Ford did for automobile manufacturing. Instead of each cell and panel being a bespoke manufacturing event with drastically different phases for it to move through, this makes a process where you dump raw materials in the front and continuous rolls of fairly cheap solar PV ready for use come out the other side.

So far there is a cost to the performance of these “roll” produced solar PV, and its in solar efficiency. Current consumer installable technology using the expensive process produces a panel of about 22%. This means of 100% of the energy the panel is exposed to under perfect light and temperature conditions, 22% of it becomes electricity coming out of the panel. This “roll” technique produces panels with only about 15% of the performance. In my mind that isn’t a dealbreaker. There are places you have way more space than money, and a lower performance, but much cheaper panel would be ideal.

Yes, if the cost is low enough that the price per Kw is less, I think we would find more places to put it. On fences, on balconies, on rooftops of course, on awnings for parking spaces, on gazebos as a shade curtain, on pavilion rooftops… Yeah

I think that’s a big if. With their (generally) shorter life expectancy they have to be half to a third of the cost of silicon panels to break even on a 20yr panel life. And that’s not including the labor to replace them.

Yes, that’s the hope. It’s still more expensive than silicon cells. But this gives it a plausible path to commercial viability.