I feel like a + shaped screw head would be as standard as a pyramid if multiple civilizations had developed screws independently. It wouldn’t be the last kind, but it would be there somewhere. Maybe even a long, long time ago.

I think a single slotted screw head would be more universal and easy. You just cut one line into the top of the screw head and your ready to go. A Philips head would need to be cut twice and once you did, you’ve weakened the head one degree more by removing more material

Slotted screws are the proof that Satan is real.

Absolutely the only benefit to slot headed screws is how easy they are to make, which is why they’re what a home machinist would make when creating his own fasteners, and why any aliens out there that use threaded fasteners have probably also tried and learned to hate them.

Most other shapes of driver aren’t cut, they’re stamped.

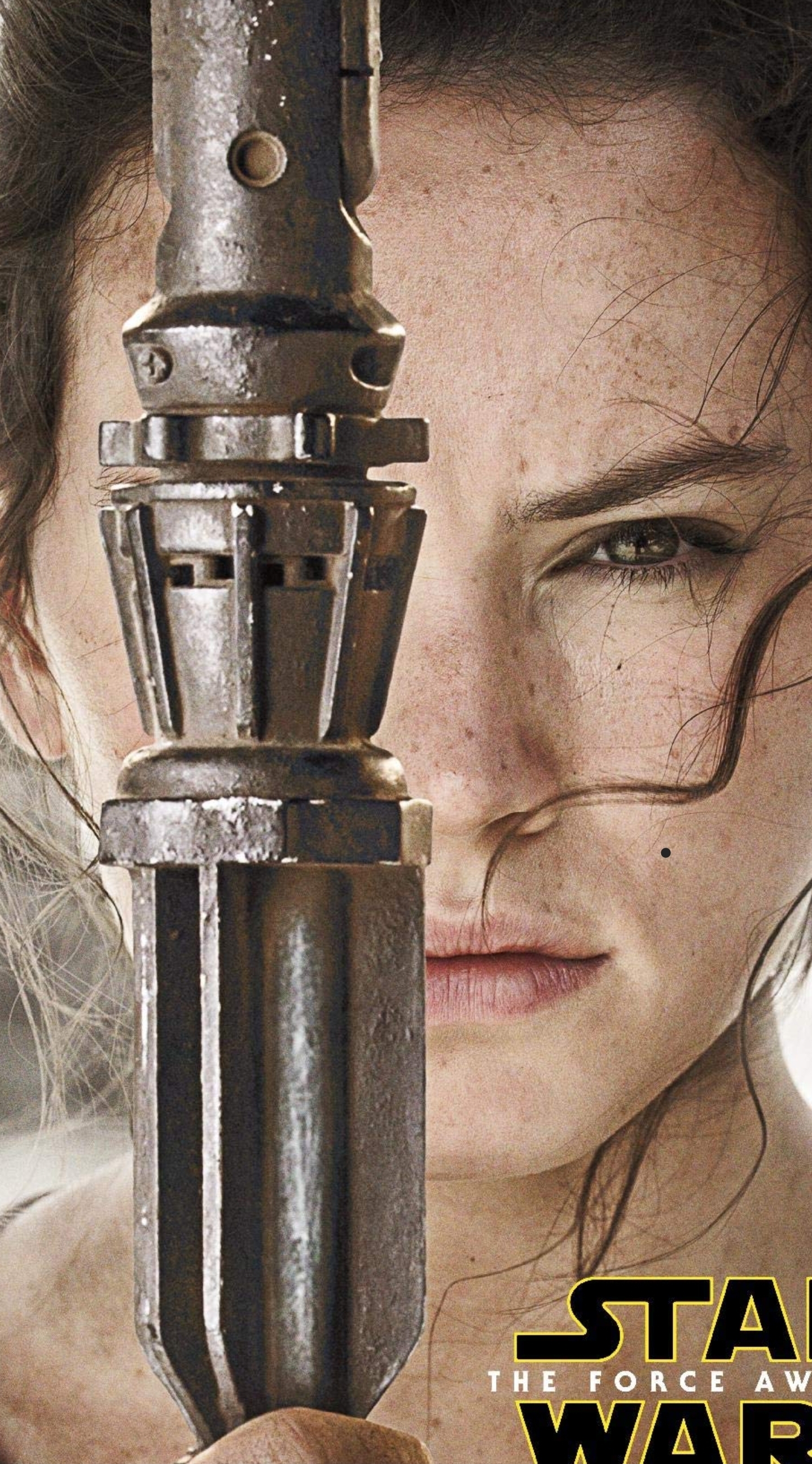

Disappointed that the first comment isn’t, “May the Torx be with you”

That may have been the actual post title I was looking for.

Even in a galaxy far far away everything is still made in china

Edit: at least they didn’t use Phillips screws

Can’t get more spacey screws than those. They basically look like galaxies

That’s because they were worried someone would have taken them off.

Hey, if it works it works.

It works, but badly. All my homies hate cam-out and love torx.

Preventing cam-out with a Phillips screw is like learning the ways of the Force. It takes patience and skill, something the Empire’s rigid Torx would never understand.

Somehow, Phillips head survived.

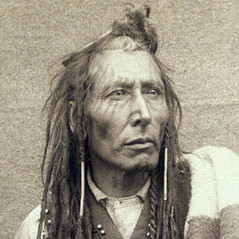

Where do you think we got it from?

You’d think that they would have switched to Pozidriv.

No wonder the Jedi failed.

Bet it’s an inch screw too

May the Philips be with you.

Could be JIS.

Thank you!

Obligatory Babylon 5 Swedish meatballs

Oh man, this is 100% real. Disney is such garbage…

Or perhaps the Jedi are also just cooking with water.